ETECH EIE is a Canadian company providing the most advanced petroleum test instruments for laboratories, ETECH offers analytical software and services. ETECH exists more than 21 years and has been proven to have the best Price/Quality in the Petroleum Analyzers. If you want to know more, contact us. We are able to provide you with Demo Instruments to experience the difference.

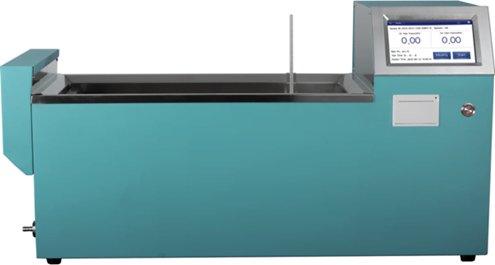

EIE-DI-01 ATMOSPHERIC DISTILLATION TESTER

ASTM D86, ASTM D850, EN ISO 3405, IP 123 and 195, DIN 51 751, NF M07-002, GB/T 6536, GB/T

3146.1, ASTM D1078

One-button Start. Automatically completes sample distillation testing, saves, prints, or uploads the measurement result data.

It can test different types of samples such as gasoline, kerosene, diesel, organic solvents, and benzene products.

The high-efficiency compressor cold circulation system has a fast cooling speed, shortens the interval of measurement, and improves its efficiency.

Flash Point testers

§ ASTM D92, ISO 2592:2017, IP 36, GB/T 3536

§ One-key start

§ Machine Vision Technology to detect flash point

§ Widely used in petroleum, electric power, railway, aviation, water transportation, national defence and scientific research etc.

§ ASTM D93-2010, ISO 2719, GB/T 261-2008

§ One-Button Start. The tester can automatically perform the ignition, heating , stirring, detection, pressure correction at flash point, printing, and colling.

§ An advanced 32-bit ARM processor, a high-precision platinum resistor, and 24-bit analog-to-digital converter.

§ The first non-contact stirring method.

§ Build-in the atmospheric pressure sensor.

§ ASTM D56, IP 170, EN ISO 1373,DEF STAN 91-091

§ Temperature range -30 - 80°C

§ Unknown sample pre-test function

§ Heating rate: 0.2 - 6°C /min continuously adjustable

§ Ignition Temperature interval: 0.1 - 3°C continuously adjustable

Constant Low Temperature Water Bath is designed by EIE using the advanced modern concept, mainly used for colleges and universities, medical, food, petrochemical, health and epidemic prevention, environmental monitoring where need low-temperature thermostatic experimental conditions for scientific research or production.

- ASTM D1322, ISO 3014, GB 382

- One-Button start

- "Machine Vision" technology adopted

- Automatic ignition system

- Automatic atmospheric pressure adjustment

- Improving the measurement accuracy, repeatability,

reproducibility, and making the data more realistic and reliable.

The Jet Fuel Smoke Point Tester, developed by Canada Etech International Enterprises Inc. (EIE), uses the most advanced international design concepts and test methods in the world, which improves the automation degree of the smoke point tester, guarantees the measurement accuracy, and minimizes the adverse consequences caused by operator errors.

EIE-RVP-2 Reid Vapor Pressure

1. ASTM D323, GB/T 8017

2. One-Button Start. The tester can automatically perform the oscillation, measuring, recording, and printing.

3. An advanced 32-bit ARM processor, advanced sensors and conditioning circuits are adopted.

4. It adopts advanced wireless data transmission technology to minimize the influence of air leakage on the test.

5. 2 Groups of detection units are equipped.

The Canadian EIE Company developed the EIE-RVP-2 Reid Saturated Vapor Pressure Tester following ASTM D323 Petroleum Product Vapor Pressure Measurement Method (Reid Method). It adopts the most advanced international design concepts and test methods. After years of research and innovation, we finally design and produce an automatic measuring instrument for petroleum products’ vapor pressure. This instrument is suitable for determining the vapor pressure of gasoline and other volatile petroleum products and volatile crude oil as specified in ASTM D323 and fully meets the precision requirements. It can be widely used in petroleum, transportation and scientific research industries or departments.

EIE-TAV-01 Total acid value

1. ASTM D3242, GB/T 12574

2. The cutting-edge “machine vision” technology.

3. Using a high-speed micro-industrial computer and industrial-grade high-fidelity high-speed cameras

4. By establishing a mathematical model, the digital image is analyzed, the end colour is automatically determined, and the total acid value is determined. Its accuracy can reach more than 5 times the current standard’s repeatability, which completely replaces artificial naked eye recognition.

The EIE-TAV-01 Automatic Total Acid Value Tester for Jet Fuel is a product independently developed by the Canadian EIE Company and has completely independent intellectual property rights. It is developed by referring to the manual titration procedure in the standard. It can completely replace manual measurement work.

This instrument adopts the cutting-edge “machine vision” technology in the international measurement and control field, realizes the automatic completion of the total acid value determination work, and opens up a new field of “machine vision” technology application.

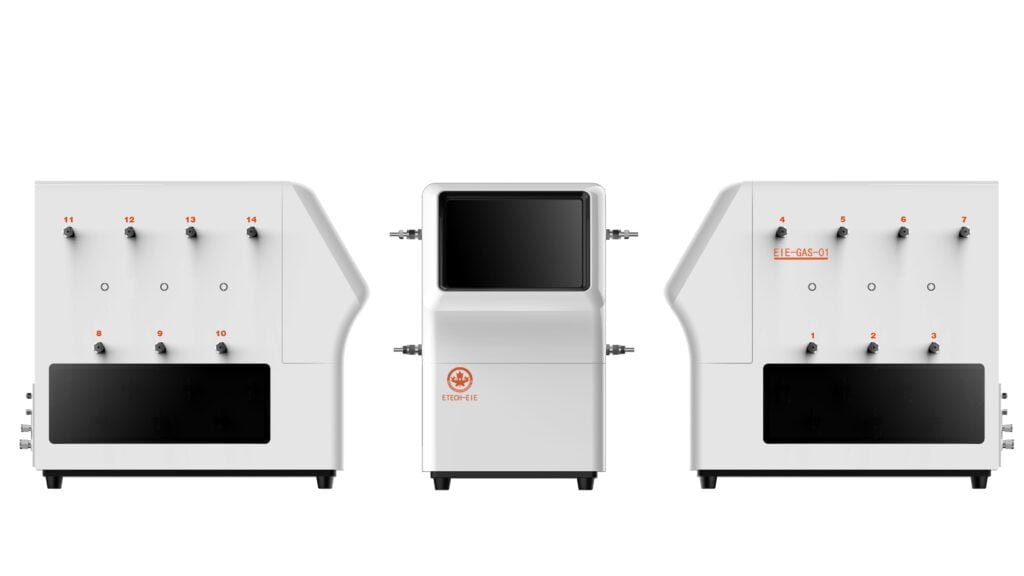

EIE-TAV-01 Sulfur and tadler bag sampler

- Improving accuracy and repeatability

- Reducing human interaction

- The instrument can connect airbags and cylinder samples

- Choosing different combinations of high, medium, and low

- The built-in inert gas purge function ensures cleanliness.

- The auto hydrogen sulfide tester developed by Canada Etech International Enterprises Inc. (EIE) replaces manual operation since the sampling rate of manual sampling is unstable. The traditional hydrogen sulfide detection tube has low accuracy. And the human observes the scale to read the value causes a relatively large error. In terms of efficiency, manual work can only make one sample at a time, which is inefficient.

- The measurement accuracy of the existing manual operation equipment is within ±15%, and our instrument can test samples which three different contents: high, medium, and low. The accuracy reaches the ppm-level. Just insert the sample taken into the corresponding inlet, and the software will start the sequence and then automatically complete the measurement of multiple samples. It dramatically improves work efficiency and reduces the contact between samples and people. Moreover, it protects the operator’s health. The accuracy and the repeatability of the analysis are improved as well.